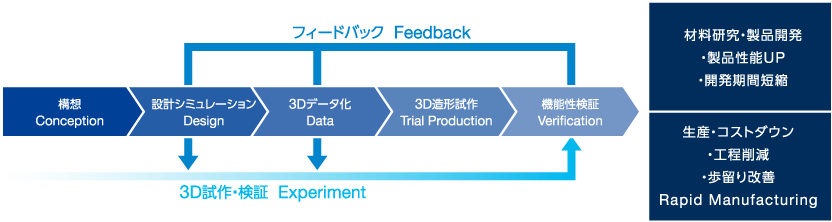

Customized 3D Printing & Verification

Flow of service

Flow of customized 3D printing of ceramics

- Conception & design

- Characteristics: Hardness, strength, electrical characteristics, thermal conductivity, dimensional accuracy

- Macrostructures, shapes: Thin plate, bulk body, etc., the basic structures of which are lattice, moth-eye structure, flow path, etc.

- Microstructures: Crystal structure, void

- Selection of materials: Preparation of materials, in terms of element, particle diameter/size, shape, purity, etc. (customer, our company)

- 3D data

- Coordination between customer and our company on design based on the degree of difficulty in 3D printing, drawing preparation

- 3D printing prototyping, coordination about design based on the degree of difficulty in 3D printing, and drawing preparation

- Adjustment of ceramic slurry properties, confirmation of basic characteristics (viscosity properties, curing depth, etc.)

- Support during 3D printing, guard design

- Whether processing is needed or not after 3D printing (application, lamination, photo-curing), cleaning, degreasing, and sintering

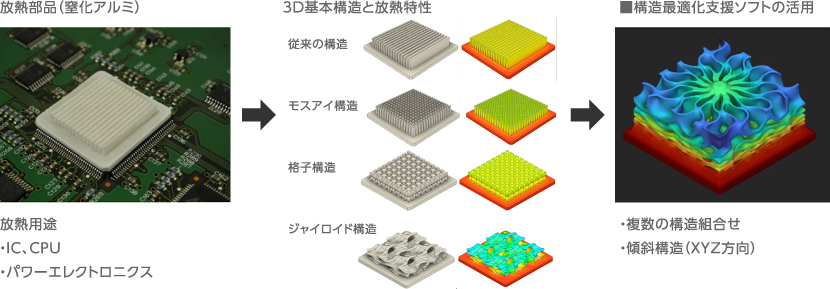

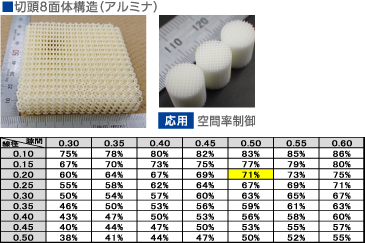

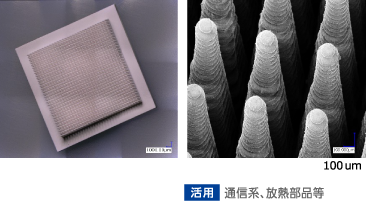

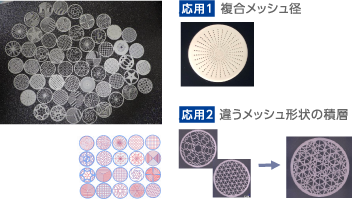

Our specialty structures

-

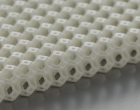

Lattice structure

-

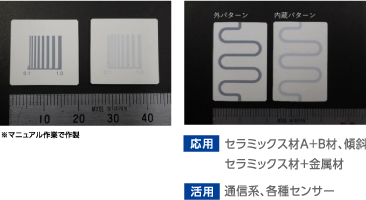

Inclined structures, combination of structures

-

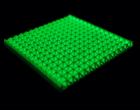

Moth-eye structure

-

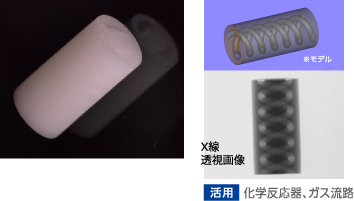

Fine flow passage structure

-

Multiple material laminated & inclined structures

-

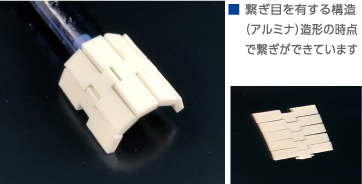

Jointed structure

-

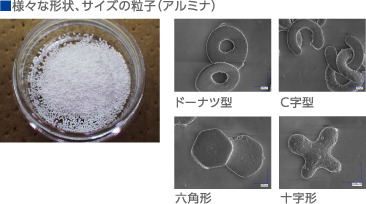

Particle shapes

-

Filters

Materials we have experience with in 3D printing

3D printing can be performed with various materials and customer materials. Why not give it a try?

-

Alumina

-

Zirconia

-

Aluminum nitride

-

Silicon carbide

-

Stainless steel

-

Silicon nitride

-

Laminated composite material

-

Phosphorescent material

(strontium aluminate)

| Materials | Features | |

|---|---|---|

| Oxides | Alumina Al2O3 | Excellent heat resistance, abrasion resistance, and insulation performance, high chemical resistance, low price |

| Zirconia ZrO2 | Excellent chemical resistance and corrosion resistance, high strength, high fracture toughness, low thermal conductivity | |

| Silicon oxide SiO2 | Insulation performance, low permittivity, piezoelectric effect, optical characteristic | |

| Yttria Y2O3 | High refractive index, insulation performance, chemical resistance | |

| Composite oxides | Phosphorescent material SrAl2O4(Eu2+) | Long afterglow (phosphorescent material) |

| Zeolite | Porous structure (ion-exchange material, adsorption material) | |

| Apatite | High biocompatibility | |

| Barium titanate | High permittivity | |

| Carbides | Silicon carbide SiC | High strength and high thermal conductivity even under high-temperature environments |

| Nitrides | Silicon nitride Si3N4 | High thermal shock resistance, high strength, low thermal expansion coefficient, excellent insulation performance |

| Aluminum nitride AlN | High thermal conductivity, high thermal shock resistance, excellent insulation performance | |

| Metals | Stainless steel | Base metal, corrosion resistance, heat resistance, workability, strength |

| Silver (Ag), copper (Cu) | Precious metals, spreadability, electric and thermal conductivity | |

| Carbon | C | Heat resistance, heating element, cutting material, polishing material |

*We also have experience in studies regarding many other materials.

About carried-in materials

Since it is necessary to select materials according to the function of ceramics, we also provide support for realization of 3D printing with carried-in materials. Please consult us.

■ Composite materials ■ Sintered metals ■ Other inorganic materials, etc.

Topology optimization

Further functional improvements may be realized by simulating the optimization of partial functions in addition to unique 3D shapes.

We will continue to challenge ourselves toward one-step-ahead device design.